-

-

-

-

• Continous repeatability of high precision system runout • Superior clamping force versus other precision clamping systems • Collet Locking-System (pat. pend.) retains collet in nut for easier assembly • Total system runout ≤3µm at 3xD • Increases tool life with precise runout • High flexibility by usage of collets with different clamping diameters • Low noise due to slotless clamping nut

• Continous repeatability of high precision system runout • Superior clamping force versus other precision clamping systems • Collet Locking-System (pat. pend.) retains collet in nut for easier assembly • Total system runout ≤3µm at 3xD • Increases tool life with precise runout • High flexibility by usage of collets with different clamping diameters • Low noise due to slotless clamping nut -

-

-

-

- High precision

- Easy operation

- For 1+2-plane Balancing

- Balancing methods: gramm, degree, split angle, drilling axial and radial, milling, fixed position.

- Display in: gmm, gramm, quality grade

- Rotor weight up to approx. 20kg

- Rotor-Ø up to 270mm

- Rotor length up to approx. 400mm

- Immediately ready to use

- Weight approx. 45kg only

-

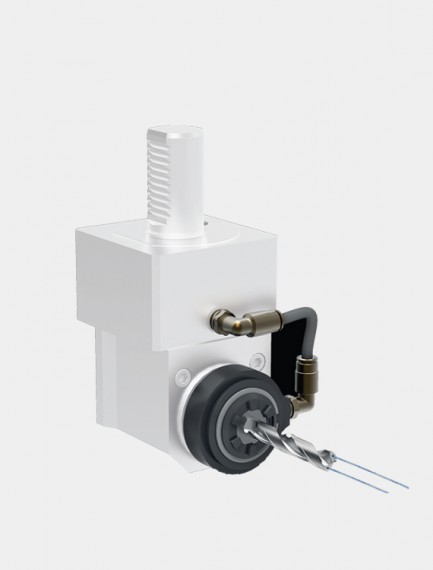

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

The TOOL MASTER Quadra is the compact tool presetting device directly for production. Technical data

The TOOL MASTER Quadra is the compact tool presetting device directly for production. Technical data- Measurement device / PC connection via USB cable.

- Inspection light as standard with1 LED (EyeRay®).

- Weight balance with tried and tested roller springs.

- Measurement system by Sylvac of Switzerland.

- Standard spindle, patented needle bearing.

- Ergonomically positioned hand wheels for fine adjustment.

- Simple table as part of the device.

-

The TOOL MASTER 5 is a universal tool presetting device used directly in production for large tools. Technical data

The TOOL MASTER 5 is a universal tool presetting device used directly in production for large tools. Technical data- 12 V supply voltage for control of the fine adjustment and the pneumatics for the spindles

- Motorised axles

- Air control unit

- Standard spindle: needle bearing, KV spindle optional

- Ergonomically positioned joystick for fine adjustment

- Selective axle clamping

- A tool cabinet is also optionally available

-

- Shrink Range Ø 3 – 20 mm for carbide shanks

- and Ø 6 – 20 mm for HSS shanks

- • Max. shrink extension 400 mm

- • Max. cooling extension 160 mm

- • Operator does not have any contact with hot tools

- • All tool nose contours may be used

- • Integrated water cooling

- • Generator in a "Black Box" for easy replacement by end users

-

- Shrink range Ø 3 – 16 mm for carbide shanks

- To shrink all TER shrink collet sizes and diameters

- • Easy shrink process by push of one button

- • Hand operation of the coil

- • Patented Shrinking process

- • Coil allows interchangeable discs for effective shrinking of tool holders and TER collets

-

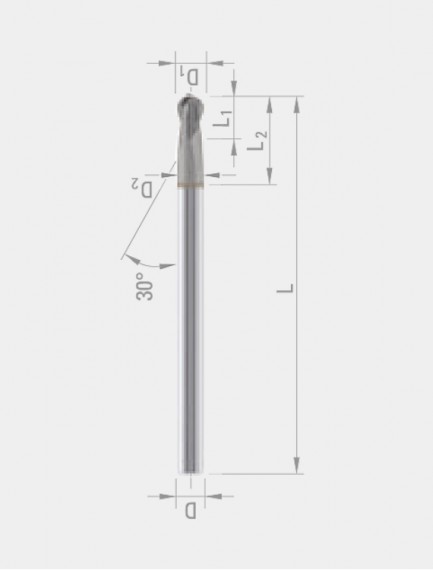

Polished Carbide BAll

Polished Carbide BAll -

Designed for high performance drilling in a broad range of materials.

Designed for high performance drilling in a broad range of materials. -

Micro drills are manufactured in up to 3 different flute lengths, depending on diameter.

Micro drills are manufactured in up to 3 different flute lengths, depending on diameter. -

-

-

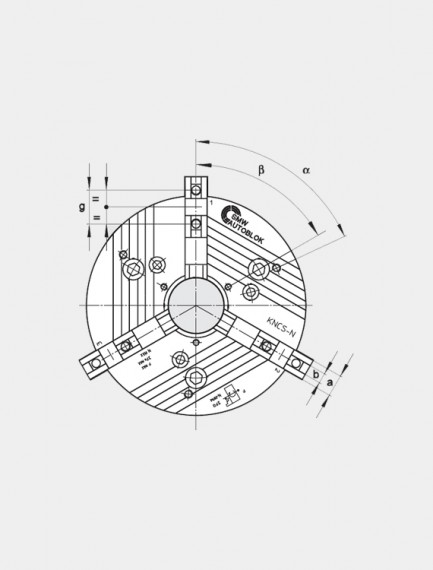

High precision power chucks Ø 125 - 400 mm

High precision power chucks Ø 125 - 400 mm- closed center

- 2 and 3 jaws (4 jaws only Ø 400 mm)

-

High precision pull-down chucks Ø 170 - 650 mm

High precision pull-down chucks Ø 170 - 650 mm- active pull-down

- tongue & groove

- 3 jaws

-

High precision power chucks Ø 130 - 450 mm

High precision power chucks Ø 130 - 450 mm- LARGE THROUGH HOLE

- 2, 3 and 4 jaws

-

Quick jaw change power chucks Ø 140 - 630 mm

Quick jaw change power chucks Ø 140 - 630 mm- LARGE THROUGH HOLE

- high speed

- high flexibility: jaws radially adjustable/reversible

- 3 jaws

-

• Recommended for general purpose reaming in most materials. • Straight flutes. • Well suited for ferrous metals and many non-ferrous and non-metallic materials. • Special sizes, shank diameters, flute lengths, step reamers, coating, etc. available as specials.

• Recommended for general purpose reaming in most materials. • Straight flutes. • Well suited for ferrous metals and many non-ferrous and non-metallic materials. • Special sizes, shank diameters, flute lengths, step reamers, coating, etc. available as specials. -

- Single Flute Gundrills

- Specification solid drilling tools, counteboring tools, trepanning tools

-

- Deep Hole Drilling Tools

- Specification new: from dia. 12.000 mm insert with serration

-

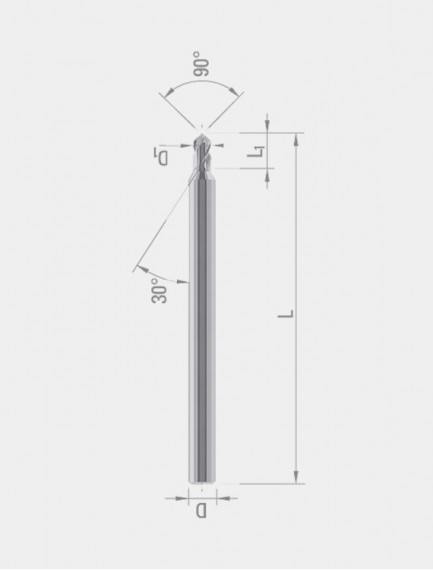

This is the original single flute countersink designed for general purpose countersinking, chamfering or deburring. • Self piloting and completely chatterless. • No secondary burs formed. • Each size may be used on a wide range of hole diameters. • Use on machine tool or in handheld tool applications. • Easily resharpened. • Tin coating for higher hardness and increased lubricity.

This is the original single flute countersink designed for general purpose countersinking, chamfering or deburring. • Self piloting and completely chatterless. • No secondary burs formed. • Each size may be used on a wide range of hole diameters. • Use on machine tool or in handheld tool applications. • Easily resharpened. • Tin coating for higher hardness and increased lubricity. -

Approved high-pressure clamping system Mechanical machine vice with continuous force adjustment. 10% to 100% of the clamping force with only 1 rotation of the hand crank and always the same final crank position. Quick adjustment of the clamping range using locking pins

Approved high-pressure clamping system Mechanical machine vice with continuous force adjustment. 10% to 100% of the clamping force with only 1 rotation of the hand crank and always the same final crank position. Quick adjustment of the clamping range using locking pins -

Standard line includes:

Standard line includes:- safety valve

- stroke control (without proximity switch)

- port for compressed air

- central lubrication grease, oil or oil + air

- swarf guard

-

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC

- Diameter tolerance: d3= ISO js4

- Chamfer f8 as assembly centering aid

-

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC induction hardened, depth 1.5+1mm

- Diameter tolerance: d1= ISO h3 superfinish ground d2= ISO js4

- Chamfer f8 as assembly centering aid

-

Smooth-edged, normal version with short neck High-performance penetration edge

Smooth-edged, normal version with short neck High-performance penetration edge -

Designed for EXTREME Productivity. Unique flute geometry reduces harmonics at increased feeds and speeds.

Designed for EXTREME Productivity. Unique flute geometry reduces harmonics at increased feeds and speeds. -

The geometry of M.A. Ford® 135 Series solid carbide end mill allows it to be run at extremely high chip loads surpassing the current market leaders.

The geometry of M.A. Ford® 135 Series solid carbide end mill allows it to be run at extremely high chip loads surpassing the current market leaders. -

-

-

-

-

-

Clamping with system Modular machine vice as clamping system, using clamping by tension. Unique, patented actuation with rapid lever, mechanical amplification and minimum set-up times.

Clamping with system Modular machine vice as clamping system, using clamping by tension. Unique, patented actuation with rapid lever, mechanical amplification and minimum set-up times. -

Duogrip for tombstones

Duogrip for tombstones -

with top jaw 5A on a DMG machine, directly clamped with 2 locating bolts on a zero point system

with top jaw 5A on a DMG machine, directly clamped with 2 locating bolts on a zero point system -

Front-end pneumatic power chucks

Front-end pneumatic power chucks- EXTRA LARGE THROUGH HOLE Ø 26 - 115 mm

- 3 jaws

- SP-ES: chuck with rapid and clamping stroke

- SP-L: chuck with long jaw stroke

-

Expanding mandrels Ø 14.7 - 129.7 mm

Expanding mandrels Ø 14.7 - 129.7 mm- Size 1 - 11

- Large expansibility 1 - 2 mm depending on size

- Flange mounting

- Very rigid design

-

Closed center rotating hydraulic cylinder

Closed center rotating hydraulic cylinder- up to 70 bar

- central bore for media supply

- stroke control via proximity switch or linear positioning system

-

Collet chuck for bar machining

Collet chuck for bar machining- Bars Ø 3 - 80

- Collets DIN 6343

-

The operation is based on elastic deformation of the diaphragm - this means - no sliding parts - no friction - centrifugal force compensation - proofline® series = fully sealed low maintenance

The operation is based on elastic deformation of the diaphragm - this means - no sliding parts - no friction - centrifugal force compensation - proofline® series = fully sealed low maintenance -

Technical data: Material: EN-JL 1040 (GG 25)

Technical data: Material: EN-JL 1040 (GG 25) -

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC

- Diameter tolerance: d3= ISO js4 (only assembly diameter)

- Chamfer f8 as assembly centering aid

-

Technical data:

Technical data:- Cage material: POM

- Ball material: 1.3505 (100Cr6)

- Ball in accordance with ISO3290, grade G10

- K = No. of balls

- C = Load in N per ball cage (standard value)

-

Technical data:

Technical data:- Cage material: 3.1645 (AlCuMgPb)

- Ball material: 1.3505 (100Cr6)

- Ball in accordance with ISO3290, grade G10

- K = No. of balls

- C = Load in N per ball cage (standard value)

-

The program of collet holders with a clamping surface is specifically designed for use on Swiss Type machines like Citizen, Manurhin, Star, Tornos, etc.

The program of collet holders with a clamping surface is specifically designed for use on Swiss Type machines like Citizen, Manurhin, Star, Tornos, etc. -

To complement our broaching tool holder we recommend our broaches, which are manufactured with the utmost care and precision. Combined with our Broaching tool holder "Made by PCM" in which our broaches are precisely matched, you get maximum productivity and compatibility.

To complement our broaching tool holder we recommend our broaches, which are manufactured with the utmost care and precision. Combined with our Broaching tool holder "Made by PCM" in which our broaches are precisely matched, you get maximum productivity and compatibility. -

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC induction hardened, depth 0.059+0.039in

- Diameter tolerance: d1= ISO h3 superfinish ground

- Chamfer f8 as assembly centering aid

-

Technical data:

Technical data:- Material of the guide elements: d1 > 25mm: 1.3505 (100Cr6), hardened 62-64HRC, d1 ≤ 25mm: 1.7131 (16MnCr5), hardened 61-63HRC

- Diameter tolerance: d1= ISO h3 superfinish ground

- Diameter tolerance: d3= ISO js4

-

Designed for high performance drilling in a broad range of materials.

Designed for high performance drilling in a broad range of materials. -

-

-

-

-

-

Shrink Range Ø 3 – 32 mm for carbide shanks and Ø 6 – 32 mm for HSS shanks • Max. shrink extension 400 mm • Max. cooling extension 160 mm • Operator does not have any contact with hot tools • All tool nose contours may be used • Generator in a "Black Box" for easy replacement by end users

Shrink Range Ø 3 – 32 mm for carbide shanks and Ø 6 – 32 mm for HSS shanks • Max. shrink extension 400 mm • Max. cooling extension 160 mm • Operator does not have any contact with hot tools • All tool nose contours may be used • Generator in a "Black Box" for easy replacement by end users -

Shrink Range Ø 3 – 32 mm for carbide shanks and Ø 6 – 32 mm for HSS shanks • Max. shrink extension 350 mm • Operator does not have any contact with hot tools • All tool nose contours may be used • Generator in a "Black Box" for easy replacement by end users

Shrink Range Ø 3 – 32 mm for carbide shanks and Ø 6 – 32 mm for HSS shanks • Max. shrink extension 350 mm • Operator does not have any contact with hot tools • All tool nose contours may be used • Generator in a "Black Box" for easy replacement by end users -

Tool Master Lite is a simple and user friendly presetter for machining wood, metal and glass. TECHNICAL DATA Location in production: Workbench Measuring range: 250 / 0 ….300 Axis fixation: Mechanics Fine adjustment: In the X-axis Tool mounting: Needle bearing SK 50 Measuring method: Measuring probe Dimensions: 420 x 150 x 590 mm / 23 kg Power supply: Battery (type AA)

Tool Master Lite is a simple and user friendly presetter for machining wood, metal and glass. TECHNICAL DATA Location in production: Workbench Measuring range: 250 / 0 ….300 Axis fixation: Mechanics Fine adjustment: In the X-axis Tool mounting: Needle bearing SK 50 Measuring method: Measuring probe Dimensions: 420 x 150 x 590 mm / 23 kg Power supply: Battery (type AA) -

The WA Tool Block is designed to make assembly and set-up as easy as a twist of the handle. The WA Tool Block comes in two versions—one rotates every 90 degrees and the other every 45 degrees. Each location has a positive stop. The toolholder head can be easily interchanged to accommodate most toolholder types.

The WA Tool Block is designed to make assembly and set-up as easy as a twist of the handle. The WA Tool Block comes in two versions—one rotates every 90 degrees and the other every 45 degrees. Each location has a positive stop. The toolholder head can be easily interchanged to accommodate most toolholder types. -

REGO-FIX’s reCool is a one-of-a-kind solution that converts existing tooling systems to utilize coolantthrough tooling. • For tools with metric male thread with ER collet • Speeds up to 12,000 rpm* • Coolant pressures up to 1,000 PSI • Coolant lubricated maintenance free bearings • For through cutter coolant (with sealing disc DS) • For peripheral coolant (with flush disc KS) • Converts existing tooling to coolant through

REGO-FIX’s reCool is a one-of-a-kind solution that converts existing tooling systems to utilize coolantthrough tooling. • For tools with metric male thread with ER collet • Speeds up to 12,000 rpm* • Coolant pressures up to 1,000 PSI • Coolant lubricated maintenance free bearings • For through cutter coolant (with sealing disc DS) • For peripheral coolant (with flush disc KS) • Converts existing tooling to coolant through -

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

-

- Counterboring Tools

- Specification deep hole drilling tools, system BTA multi-cutter with 3 indexable cutting inserts