-

-

-

-

• Continous repeatability of high precision system runout • Superior clamping force versus other precision clamping systems • Collet Locking-System (pat. pend.) retains collet in nut for easier assembly • Total system runout ≤3µm at 3xD • Increases tool life with precise runout • High flexibility by usage of collets with different clamping diameters • Low noise due to slotless clamping nut

• Continous repeatability of high precision system runout • Superior clamping force versus other precision clamping systems • Collet Locking-System (pat. pend.) retains collet in nut for easier assembly • Total system runout ≤3µm at 3xD • Increases tool life with precise runout • High flexibility by usage of collets with different clamping diameters • Low noise due to slotless clamping nut -

-

-

-

- High precision

- Easy operation

- For 1+2-plane Balancing

- Balancing methods: gramm, degree, split angle, drilling axial and radial, milling, fixed position.

- Display in: gmm, gramm, quality grade

- Rotor weight up to approx. 20kg

- Rotor-Ø up to 270mm

- Rotor length up to approx. 400mm

- Immediately ready to use

- Weight approx. 45kg only

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

- Reduce machine downtimes

- Machine complex parts, even when the space is normally inaccessible (internal machining)

- Optimize machining cycles

- Reduce the amount of having to re-position work pieces to a minimum

- We offer you standard angle heads as well as specialty heads developed specifically for your manufacturing requirements.

BENZ angle heads will help you:

-

The TOOL MASTER Quadra is the compact tool presetting device directly for production. Technical data

The TOOL MASTER Quadra is the compact tool presetting device directly for production. Technical data- Measurement device / PC connection via USB cable.

- Inspection light as standard with1 LED (EyeRay®).

- Weight balance with tried and tested roller springs.

- Measurement system by Sylvac of Switzerland.

- Standard spindle, patented needle bearing.

- Ergonomically positioned hand wheels for fine adjustment.

- Simple table as part of the device.

-

The TOOL MASTER 5 is a universal tool presetting device used directly in production for large tools. Technical data

The TOOL MASTER 5 is a universal tool presetting device used directly in production for large tools. Technical data- 12 V supply voltage for control of the fine adjustment and the pneumatics for the spindles

- Motorised axles

- Air control unit

- Standard spindle: needle bearing, KV spindle optional

- Ergonomically positioned joystick for fine adjustment

- Selective axle clamping

- A tool cabinet is also optionally available

-

- Shrink Range Ø 3 – 20 mm for carbide shanks

- and Ø 6 – 20 mm for HSS shanks

- • Max. shrink extension 400 mm

- • Max. cooling extension 160 mm

- • Operator does not have any contact with hot tools

- • All tool nose contours may be used

- • Integrated water cooling

- • Generator in a "Black Box" for easy replacement by end users

-

- Shrink range Ø 3 – 16 mm for carbide shanks

- To shrink all TER shrink collet sizes and diameters

- • Easy shrink process by push of one button

- • Hand operation of the coil

- • Patented Shrinking process

- • Coil allows interchangeable discs for effective shrinking of tool holders and TER collets

-

Polished Carbide BAll

Polished Carbide BAll -

Designed for high performance drilling in a broad range of materials.

Designed for high performance drilling in a broad range of materials. -

Micro drills are manufactured in up to 3 different flute lengths, depending on diameter.

Micro drills are manufactured in up to 3 different flute lengths, depending on diameter. -

-

-

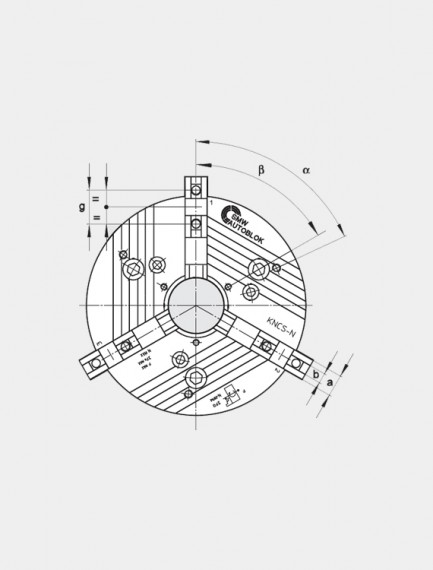

High precision power chucks Ø 125 - 400 mm

High precision power chucks Ø 125 - 400 mm- closed center

- 2 and 3 jaws (4 jaws only Ø 400 mm)

-

High precision pull-down chucks Ø 170 - 650 mm

High precision pull-down chucks Ø 170 - 650 mm- active pull-down

- tongue & groove

- 3 jaws

-

High precision power chucks Ø 130 - 450 mm

High precision power chucks Ø 130 - 450 mm- LARGE THROUGH HOLE

- 2, 3 and 4 jaws

-

Quick jaw change power chucks Ø 140 - 630 mm

Quick jaw change power chucks Ø 140 - 630 mm- LARGE THROUGH HOLE

- high speed

- high flexibility: jaws radially adjustable/reversible

- 3 jaws

-

• Recommended for general purpose reaming in most materials. • Straight flutes. • Well suited for ferrous metals and many non-ferrous and non-metallic materials. • Special sizes, shank diameters, flute lengths, step reamers, coating, etc. available as specials.

• Recommended for general purpose reaming in most materials. • Straight flutes. • Well suited for ferrous metals and many non-ferrous and non-metallic materials. • Special sizes, shank diameters, flute lengths, step reamers, coating, etc. available as specials. -

- Single Flute Gundrills

- Specification solid drilling tools, counteboring tools, trepanning tools

-

- Deep Hole Drilling Tools

- Specification new: from dia. 12.000 mm insert with serration

-

This is the original single flute countersink designed for general purpose countersinking, chamfering or deburring. • Self piloting and completely chatterless. • No secondary burs formed. • Each size may be used on a wide range of hole diameters. • Use on machine tool or in handheld tool applications. • Easily resharpened. • Tin coating for higher hardness and increased lubricity.

This is the original single flute countersink designed for general purpose countersinking, chamfering or deburring. • Self piloting and completely chatterless. • No secondary burs formed. • Each size may be used on a wide range of hole diameters. • Use on machine tool or in handheld tool applications. • Easily resharpened. • Tin coating for higher hardness and increased lubricity. -

Approved high-pressure clamping system Mechanical machine vice with continuous force adjustment. 10% to 100% of the clamping force with only 1 rotation of the hand crank and always the same final crank position. Quick adjustment of the clamping range using locking pins

Approved high-pressure clamping system Mechanical machine vice with continuous force adjustment. 10% to 100% of the clamping force with only 1 rotation of the hand crank and always the same final crank position. Quick adjustment of the clamping range using locking pins -

Standard line includes:

Standard line includes:- safety valve

- stroke control (without proximity switch)

- port for compressed air

- central lubrication grease, oil or oil + air

- swarf guard

-

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC

- Diameter tolerance: d3= ISO js4

- Chamfer f8 as assembly centering aid

-

Technical data:

Technical data:- Material: 1.3505 (100Cr6)

- Hardness: 62+2HRC induction hardened, depth 1.5+1mm

- Diameter tolerance: d1= ISO h3 superfinish ground d2= ISO js4

- Chamfer f8 as assembly centering aid

-

Smooth-edged, normal version with short neck High-performance penetration edge

Smooth-edged, normal version with short neck High-performance penetration edge -

Designed for EXTREME Productivity. Unique flute geometry reduces harmonics at increased feeds and speeds.

Designed for EXTREME Productivity. Unique flute geometry reduces harmonics at increased feeds and speeds. -

The geometry of M.A. Ford® 135 Series solid carbide end mill allows it to be run at extremely high chip loads surpassing the current market leaders.

The geometry of M.A. Ford® 135 Series solid carbide end mill allows it to be run at extremely high chip loads surpassing the current market leaders.